As you finalize your box design and are getting ready to print your custom boxes, you may have questions about which process will work best for you. First, you’ll need to decide between litho printing and direct printing. Though both processes use the latest technology to create crisp prints, the method you choose will ultimately depend on your specific needs. In this post, we’ll explain the difference between direct and litho printing methods.

If you need a more basic, less expensive, and perhaps faster printing process, then you may want to consider direct printing. The process is just as the name would imply: here, the colored ink is stamped “directly” onto your corrugated box through the use of a printing plate. Depending on the number of different colors used in your design, it may need to make a second pass through the machine. The direct printing process uses flexographic, or “flexo”, technology, and is ideal for clients that have settled on a design and would like to keep their custom printing plates for a longer period of time. It can also be more economical than litho printing, saving you money as you get your business off the ground or work to get out of the red. If the graphics on your box are more minimalist in nature, this may be the process for you.

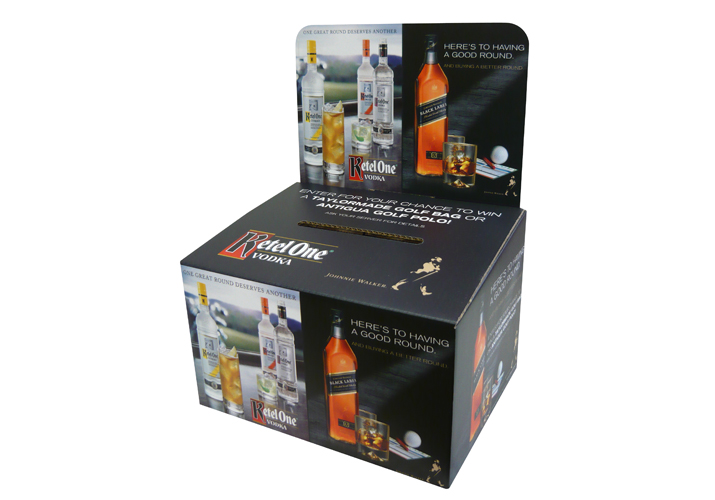

To help our customers obtain a high-end, magazine-quality look, we offer 4-color-process (CMYK) litho printing. Litho printing uses customized printing plates to transfer your design onto another sheet, which is then laminated to your box. What’s special about this process is that the design is exceptionally clear and vibrant. If you’re printing specific pictures and not just blocks of color on your boxes, the litho process ensures your images will be as clear as a photograph. It’s also a great way to make any image stand out – literally!

You can choose between different finishes like glossy or matte. Usually, litho printing is used to create a high-end feel, and is ideal for companies that are concerned about the clarity of their graphics. The litho process also works well for companies with some extra room in their budget for packaging, as well as for newer companies looking to get a leg up on their competition through gorgeous, eye-catching packaging. If your primary concern is clear graphics, getting the best box colors, or creating sophisticated, chic packaging, then litho printing may be the way to go.

Custom Boxes Now is proud to be among the top manufacturers of cardboard boxes. No matter what printing method you decide to go with, we work hard and use the latest technology to make sure that every package comes out perfectly. If you have any questions or would like to get more detailed advice about which method will work for a specific design, please don’t hesitate to contact us.

To start your own project, start building your own custom shipping boxes, folding cartons, or contact us and we’ll help you with all your questions.