Packaging is more than a protective shell around your products. It makes a powerful first impression, shaping how customers perceive your brand from the moment they see it. Think of it as a strategic asset that can drive satisfaction, build loyalty and boost your bottom line.

With countless materials, formats and finishes to choose from, finding the perfect fit can feel overwhelming. Whether you’re launching something new or refining an existing product, packaging selection principles empower you to make confident choices that elevate your brand and delight your customers.

Beyond aesthetics or logistics, packaging is often the first physical touchpoint between your product and your customer, making it a powerful tool for shaping perceptions, building trust and influencing purchasing decisions.

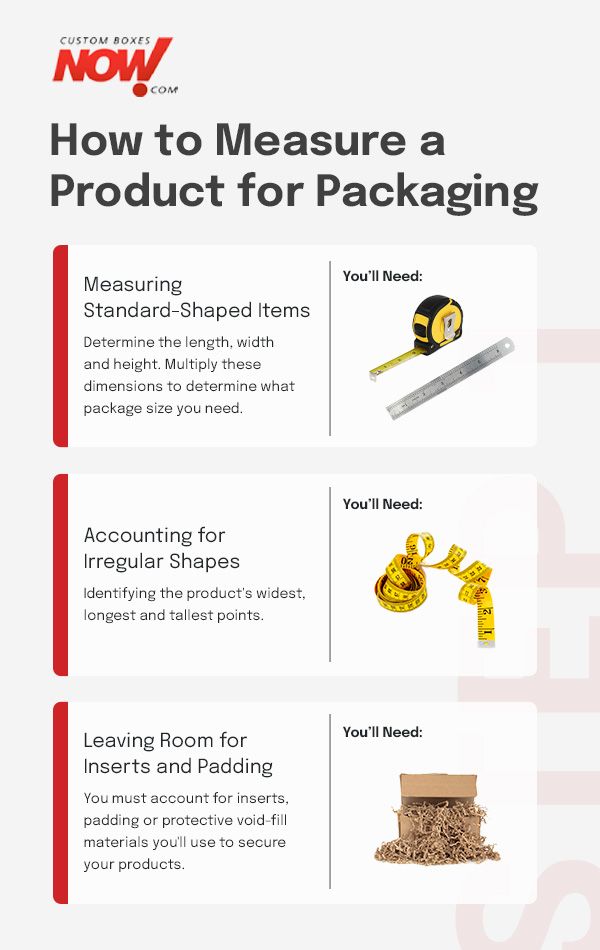

Start with understanding your product’s dimensions and travel requirements. Measuring ensures a tight, secure fit that protects your items during shipping and handling. Plus, sturdy and attractive materials can create a positive unboxing experience that delights customers. Knowing how to measure products and choosing a suitable box for shipping can save time, reduce costs and prevent item damage.

Measuring conventional items like boxes, books, cans or bottles is straightforward. You’ll need a measuring tape or ruler to determine the length, width and height. For cylindrical items, gather the height and diameter of the products. Regardless of shape, always measure from your product’s widest points to ensure a snug fit. Multiply these dimensions to determine what package size you need, always double-checking your measurements for accuracy. Even minor errors can lead to improper fits or inadequate protection, increasing the chance of damage.

Irregularly shaped items like tools require more attention. Begin by identifying the product’s widest, longest and tallest points. Use a flexible measuring tape to measure these points, as rigid rulers will not provide accurate figures. For highly complex shapes, consider using 3D scanning tools for precise data collection. Your packaging should accommodate the product’s full profile without bending it or forcing any of its components out of place. It’s also wise to test how well the item fits in your packaging to ensure adequate protection before purchasing materials in bulk.

After collecting product measurements, you must account for inserts, padding or protective void-fill materials you’ll use to secure your products. Drops or harsh impacts can damage even the most durable items. Inserts and padding absorb shocks, dampen vibrations and stabilize products throughout transit.

Fragility is another variable that can

Glassware, electronics and other breakables thrive with bubble wrap padding that absorbs shock and prevents damage. For lighter, sturdier products, air pillows or paper void fill offer a soft, flexible cushion that keeps items snug and secure during transit.

Depending on the fragility of your products, you might want to consider some material types over others. For example, fragile items like glassware and electronics can benefit from bubble wrap padding. Alternatively, you can use air pillows or paper void fill to fill gaps and provide a soft cushion for lightweight, sturdy items.

Your selected packaging material affects product protection, cost efficiency, brand perception and sustainability. Its quality is your first line of defense, ensuring items safely survive the rigors of shipping and handling.

Whether you need to ship fragile electronics or lightweight retail goods, think of your packaging as an asset that helps you avoid costly returns, reduce waste and provide a seamless customer experience.

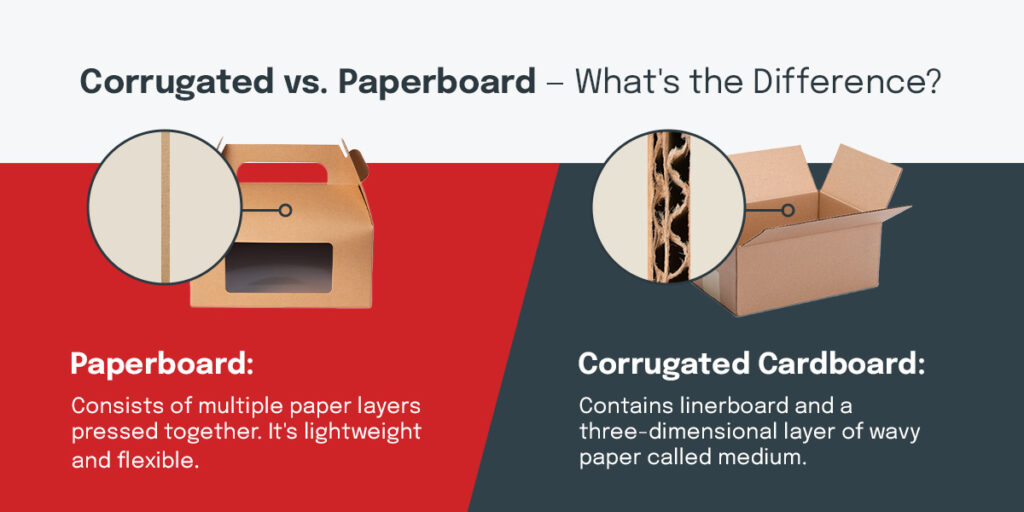

Corrugated cardboard and paperboard are two widely used packaging materials. Since they offer unique advantages, you should compare which is a better match for your product’s fragility, weight and presentation needs.

Paperboard, also known as chipboard, consists of multiple paper layers pressed together. It’s lightweight and flexible, which is excellent for retail packaging, product sleeves and cosmetic cartons. The smooth surface also allows for detailed graphics and vibrant colors, making it an ideal branding opportunity. However, paperboard doesn’t provide much cushioning and is not suitable for fragile, heavy or sharp items.

Corrugated cardboard contains linerboard and a three-dimensional layer of wavy paper called medium. There are several reasons to use corrugated cardboard, including enhanced item protection, cost-effectiveness and sustainability. Corrugated cardboard also offers more customization than standard cardboard, with signature strength and cushioning properties. It’s a wise choice for shipping boxes, protective packaging and any application where durability is essential.

Box strength is a critical factor in ensuring your packaging can withstand the rigors of shipping and handling. Two tests can determine how much a carton can carry without losing integrity.

Higher ratings on these tests equal more durability. Check the manufacturer’s certification stamp to determine these measurements. Often, you can find this information on the bottom flaps of a box. This stamp can also tell you whether a box is double-wall or single-wall, another factor in choosing adequate packaging materials.

Ultimately, selecting the appropriate box strength depends on your product’s weight and shipping method or environment. It’s safe to transport lightweight items using single-walled corrugated boxes with lower ECT ratings, while bulkier products often require double-walled corrugated boxes with higher ECT or burst strength ratings.

Always consider the total packed weight when analyzing strength ratings, including inserts and padding. Additionally, you should evaluate the shipping environment, as longer distances or rough handling may require sturdier materials. If you’re unsure which strength you need, consider building a prototype box to test functionality.

Since packaging does much more than shield products from damage, you must find strategic solutions that reflect your brand’s value and influence positive customer perceptions while respecting your bottom line.

Your packaging is an extension of your business identity. You already use colors, fonts and designs to reflect your brand’s personality, so extending those into your packaging builds recognition and trust. Think of box customizations as a way to establish a more personal connection with your customers. You can use printing to communicate relevant information, such as warnings or instructions, or stand out from competitors with eye-catching logos and designs. Choose from three primary printing methods to meet your needs.

Cost-effectiveness is pivotal when selecting packaging materials — but being budget-conscious doesn’t mean indiscriminately cutting corners. From premade boxes to fully custom designs, you’ll have several options to compare. Look for savings opportunities like bulk ordering, but don’t lose sight of how materials, printing, shipping and assembly factor into your total investment.

Start by prioritizing must-haves — protection, compliance and durability. Then, explore how smart packaging choices can elevate your brand, turning every shipment into a memorable customer experience.

Void fill refers to the materials used to pack empty spaces in packaging. While this may seem like a minor expense, it can quickly add up, especially if you have high shipping volumes. Protecting your items is essential, but you can still reduce spending in this category without compromising product safety.

First, choose the appropriate packaging sizes. Using boxes that closely match your product’s dimensions reduces the amount of empty space. Alternatively, oversized boxes require more filler, which increases material and shipping costs.

Luckily, you have budget-friendly alternatives. For example, crumpled paper is eco-friendly and costs less than bubble wrap or foam. The lightest, most accessible material that still provides appropriate cushioning for fragile items will often be the most economical.

Sustainability is an increasingly crucial factor in environmentally responsible packaging decisions that meet customer expectations. Minimizing material use is one of the most effective ways to make packaging more sustainable. Measuring products to fit their containers and reducing the need for void fill cuts down material costs and reduces waste. Eliminating unnecessary layers also reduces your environmental footprint without sacrificing product protection.

You should also consider biodegradable and recyclable packaging. Biodegradable materials break down naturally over time, reducing landfill waste. Recyclable materials, like corrugated cardboard, are reusable to conserve resources and energy. Look for labeling and certifications to ensure your packaging meets recognized environmental standards.

Does your product need custom packaging? Custom Boxes Now has over six decades of experience creating boxes for businesses just like yours. With multiple printing methods, superior service and several corrugated box styles, our team has everything you need to find packaging that meets your size, strength and sustainability needs. Connect with us to learn more about how we can tailor solutions to your needs.