When choosing the best packaging material for your business, it’s essential to weigh chipboard versus cardboard options. The choice of packaging material can make or break your business’s success. While design aesthetics matter, selecting the appropriate materials based on structural integrity and protection for goods is paramount.

This comprehensive guide will help you understand the key differences between chipboard and corrugated cardboard options, allowing you to make an informed decision about your packaging needs.

Chipboard is often constructed from recycled paper (not wood, as the name might suggest) that has been layered and pressed into various thicknesses. It’s a dense and rigid material, making it less likely to bend or break during handling and transportation.

Chipboard is used for the following:

Chipboard boxes are usually partitioned into rows to protect each product. They are also recyclable, making them eco-friendly.

When people think of the term “cardboard box,” they often envision corrugated boxes. If the box you’re picturing has fluted, fan-like folds pressed between two sturdy layers of cardboard, that’s a corrugated box.

Corrugated cardboard is a multi-layer structure featuring a middle flute layer and two outer layers. Corrugated boxes are used for shipping bulky and heavier items like large appliances and electronics or fragile items like plants and jewelry. They are also used for product displays since they can handle stacked loads and are durable enough to withstand the normal wear and tear of life in a popular store.

Corrugated boxes are often made from recycled materials, making them an environmentally responsible option. In fact, corrugated cardboard is one of the most widely recycled materials, with a recycling rate of 93% in the United States.

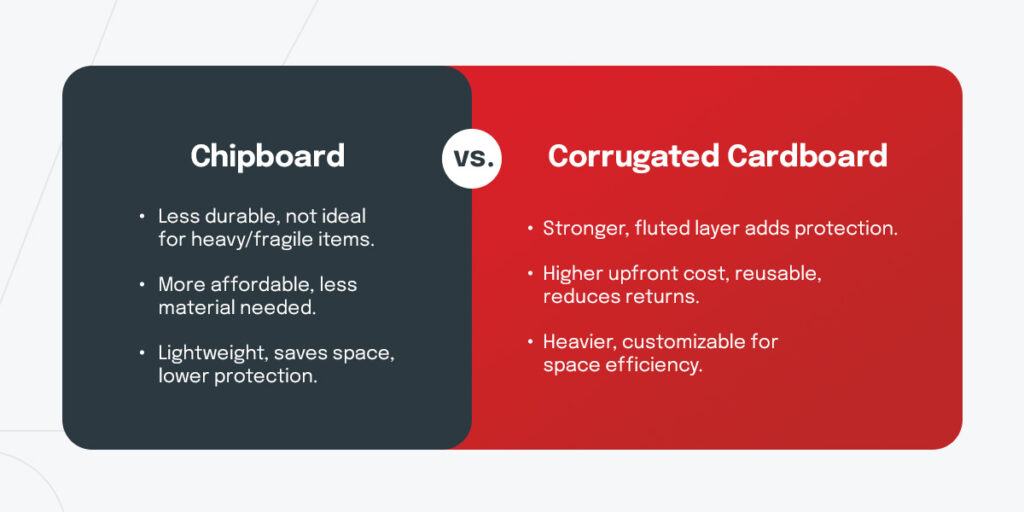

While chipboard and corrugated are both used for packaging, they have distinctions making them suitable for various applications. Explore these differences below.

Corrugated cardboard offers superior strength and durability compared to chipboard. The fluted layer between the two outer layers of corrugated cardboard provides additional protection and cushioning, making it ideal for shipping heavier or fragile items. Chipboard, while sturdy, may not offer the same level of protection for bulky or delicate products.

Chipboard packaging is often more affordable, requiring less material and processing. Corrugated cardboard boxes have higher upfront costs but are reusable. Additionally, they ensure fragile items are safe during shipping and handling, allowing businesses to save money in returns and refunds.

Chipboard boxes usually take up less space and weigh less than corrugated boxes. Their lightweight compactness can be advantageous for businesses looking to minimize shipping costs and optimize storage space. However, the space and weight savings may come at the expense of reduced protection for the products inside. Corrugated boxes also come in various styles and sizes, some of which may be more space-efficient.

When weighing chipboard vs cardboard for your packaging needs, consider the following factors:

Ultimately, corrugated cardboard is ideal for most business packaging needs, offering strength, durability, customization options and eco-friendliness.

While both materials have their merits, corrugated cardboard is the best choice for businesses looking for optimal product protection, customization options, and sustainability.

Custom Boxes Now specializes in creating custom corrugated cardboard shipping boxes that protect your products better than stock-sized boxes. Our customized creations also promote your brand through eye-catching printed designs. With our industry-leading lead times, state-of-the-art print capabilities, pre-press expertise and structural design experience, we provide a one-stop solution for all your packaging needs.

Contact us today to discuss your requirements and let our experts guide you toward the perfect packaging solution for your business.