Have you ever taken a product to the post office and discovered an overwhelming wall of different-sized boxes? When boxes are flat, it can be challenging to tell which is best fit for what you need to ship. Factors to consider include your product’s size, plus the space protective padding will take up inside the box.

The correctly sized box prevents damage and reduces shipping costs. No one wants to receive a package that’s mostly air with a small product rattling around inside it. Learn how to measure box dimensions for shipping and choose the best box for your shipments.

We measure shipping boxes in three dimensions — length, width and height.

These three measurements can help you find a box’s volume, or how much space it has inside. To find a shipping box’s volume in cubic inches, multiply its length by width by height. Then, calculate the total volume of the items you want to include and divide the two numbers.

For example, if your box is 2,160 cubic inches and the objects you want to pack take up 81 cubic inches, you can theoretically fit 26.7 items in that carton. However, you’ll also need to account for packaging materials like bubble wrap, space for the box’s flaps and seams and air gaps between items.

Measuring cylinders, spheres and pyramids can be tricky. Thankfully, you can use straightforward equations to determine the size of oddly shaped objects. After calculating the volume, you should consider additional space for padding material.

Measuring your items before selecting packaging saves time and avoids guesswork. If you’re working with multiple oddly shaped products, consider wrapping them into more uniform shapes to make measuring easier and ensure a better fit. Once you’ve prepped and sized your items, you can confidently choose a box that accommodates them.

First, grab a tape measure. Most box measurements in the United States are in inches, while most other countries use centimeters. Again, measure the product, then the box.

It doesn’t matter whether you choose U.S. measurements or the metric system, as long as you are consistent and precise. If your measurement falls between marks, round up. It’s better to have extra room than a fit that’s too tight.

Depending on a box’s thickness, its internal and external dimensions may differ significantly. That’s why you should always calculate both these numbers.

Measuring a box’s interior is the best way to ensure products will fit securely inside. Fragile products always need protective material like bubble wrap. Putting them inside a perfectly sized container won’t protect them from impact damage. You need a box that allows room for wrapping without being so large that wrapped items can shift around a lot in transit.

Measuring a box’s exterior determines if it meets shipping requirements. Some shipping companies limit box sizes, so check with your carrier before packaging products. Box size and weight can impact shipping costs, affecting your bottom line.

Sometimes, sending products individually may cost less than shipping several items inside the same box, but that depends on what you send and your chosen delivery service. Sometimes, it’s cheapest to ship in bulk, inside boxes that don’t allow goods to shift around during transit.

Accurately measuring a corrugated box involves calculating the internal and external dimensions. Corrugated cardboard comes in different thicknesses, which means the inside and outside of the box can have noticeably different measurements. Consider the thickness of the box and the protective materials you plan to put inside.

For example, imagine a box made of 1/4-inch-thick cardboard. On the outside, the box measures 8 inches by 6 inches by 4 inches. However, the cardboard’s 1/4-inch thickness means the interior only measures 7 1/2 inches by 5 1/2 inches by 3 1/2 inches, so this box isn’t big enough for an eight-inch-long product.

Even the thinnest protective materials can quickly increase the available space inside a shipping box — especially when you layer wrap, padding or dividers between items. Choose a box that allows room for cushioning without being so large that items slide around during transit. Striking this balance prevents damage and ensures efficient packing.

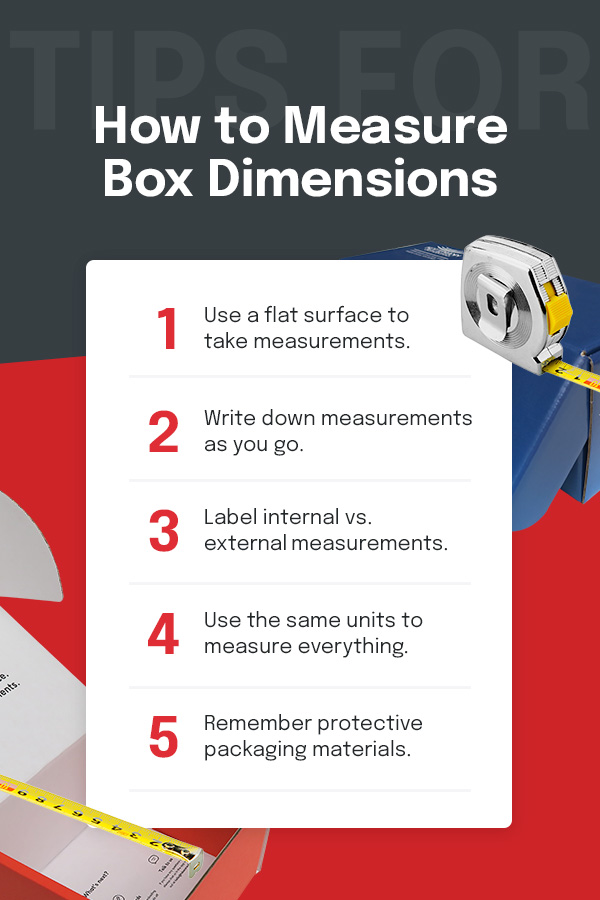

When you’re measuring box dimensions, several steps can help you get the best results. Follow these tips for how to measure a box size accurately:

When measuring a flat box, don’t include the flaps. Imagine what the carton will look like once you’ve bent and taped it into place. Then, measure the finished box’s length, width and height to get the most precise measurement of how large the shipping box will be outside.

Careless mistakes can make it challenging to choose the appropriate shipping box. Here are some tips to help you avoid these errors and get accurate dimensions the first time:

Take your time and verify all measurements to ensure you’ve written down the correct numbers. Determining a shipping plan before ordering boxes will save you time and money.

While some protective wrapping is thin, others take up extra space inside the box. Consider using corrugated cardboard separators or molded fiber packaging. In some cases, protective wrapping can completely change the shape and size of products. Knowing how much room you have to work with inside a shipping box equips you to choose the most cost-effective packaging and shipping options.

Shipping carriers calculate costs based on actual weight or dimensional weight — whichever is higher.

Dimensional weight reflects the box’s size instead of its heaviness. Dividing the box’s volume by a carrier-specific number will give you this total. Even lightweight packages can incur higher charges if they take up lots of space, so both measurements are essential for getting an accurate estimate.

U.S. parcel carriers use different DIM divisor numbers, so verify with your chosen service. After completing this calculation, parcel carriers round up to the next whole pound or kilogram. Once you understand this process, you can appreciate that right-sizing your shipping box can drastically reduce your billed shipping weight.

For example, consider a 10-pound shipping box on a scale with packaged products inside. You could send it in two different boxes.

You can lower shipping costs by right-sizing boxes to your products, finding a trustworthy carrier with a higher DIM divisor and only shipping boxes that fall below weight limits. Large boxes sometimes require freight shipping, so sending products in several smaller boxes rather than one large box may save you costs.

If you’re looking for an easy way to measure shipping boxes, try free online box measurement calculators. These calculators can help you calculate the volume of oddly shaped products and containers, so you can determine if they’re the best size to ship your products.

Fortunately, most shipping boxes are a standard size, so you can quickly calculate their volume with the easy length x width x height formula. Professional custom box companies can also answer any questions you have about choosing the best-sized box for your product.

Do you still have questions about how to measure a box for shipping? Here are several frequently asked questions and answers so you can make the best decisions about your products.

Boxes are three-dimensional objects, measured by their length, width and height. If you draw a square, you only need to measure two sides — the square’s height and width. A third measurement signifies how three-dimensional objects take up space.

If your box is unusually shaped, you can break it into several smaller areas to measure it. For example, you can measure a rectangular box with a triangular shape on the top separately as a rectangle and a pyramid. Determining a box’s volume will give you an accurate idea of how many products will fit inside and whether it’s the appropriate shape and size for your needs.

First, measure the products you want to ship. Once you know their size and have accounted for the added bulk of packaging materials, you can calculate a box’s volume.

Shipping boxes should closely fit the size of your wrapped product. Depending on the order, bulk shipping may be the most economical choice. The best box depends on the size and number of products you’re shipping, and how much packaging protection they require.

Loose space inside a container is a recipe for trouble. Items that shift during transit are more likely to arrive bent, dented or scratched. Even protective materials can cause harm if they move around too much. To avoid this, measure your products and select a box that fits them snugly. If extra space remains, fill it strategically with cushioning like molded fiber, bubble wrap or crumpled paper. Packing multiple items together can be an ideal way to maximize space and minimize movement — but be sure the box still closes securely without bulging.

Looking for high-quality boxes made in the U.S.? At Custom Boxes Now!, we’ve met customers’ unique needs for over 50 years. Our Build Your Box tool lets you choose your box style, inside dimensions, strength, color and printing options.

We provide a free structural sample and complete design, prepress and manufacturing in-house. Include a graphic or personalized design with our digital, flexo and litho printing capabilities. Compared to competitor lead times of three to four weeks, we’ll get you boxes you can use in seven days or less. Use our Build Your Box tool today or contact us for more information!